| Sign In | Join Free | My xpandrally.com |

|

| Sign In | Join Free | My xpandrally.com |

|

| Categories | Engineering Steel Bar |

|---|---|

| Brand Name: | CF Steel |

| Model Number: | 1.7225, SCM440, SAE4140, 42CrMo |

| Certification: | ISO / Mill Test Certificate |

| Place of Origin: | CHINA |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C, D/P, Western Union |

| Supply Ability: | 5000 tons / month |

| Delivery Time: | within 15 working days |

| Packaging Details: | Standard Export Packing or for Customers' Request |

| Heat Treatment: | Annealed / Q+T |

| Delivery condition: | Hot rolled or Forged |

| Test: | SGS / UT 100% / Element testing |

| Surface: | Black |

| Standard: | AISI, ASTM, DIN, GB |

| Process: | EAF+LF+VD+IC |

| Shape: | Flat bar |

| Performance: | High hardness and good machinability |

| Flaw detection: | CC / DD/ EE |

| Our Service: | CIF / FOB / EXW |

Hot Rolled Steel Flat Bar SCM440 4140 1.7225 42CrMo For Mechanical Gear Bolt Use

1. Chemical Composition (%)

| C | Si | Mn | Cr | Mo | P | S | Ni |

| 0.38~0.45 | 0.17~0.37 | 0.50-0.80 | 0.90~1.20 | 0.15-0.25 | ≤0.03 | ≤0.03 | ≤0.25 |

2. Application

It's application is as below:

A. The section of large forgings

B. Locomotive traction gears

C. The rear axle

D. The connecting rod

E. The spring load clip

F. Oil drill pipe joints

G. Fishing tools.

2. Features

1) Weldability suffers with increasing chromium content;

2) High temperature strength and high pressure hydrogenation

properties are promoted by chromium and molybdenum;

3) Molybdenum significantly reduces temper brittleness;

4) Chromium renders steel oil hardenable and increase

hardenability;

5) Chromium molybdenum high tensile steel with yield strength of

550N/mm2;

3. Mechanical Properties

Tensile strength:σb (MPa):≥1080(110)

Yield strength:σs (MPa):≥930(95)

Elongation:δ5 (%):≥12

Section shrinkage:ψ (%):≥45

Impact work:Akv (J):≥63

Impact toughness value:αkv (J/cm²):≥78(8)

4. Available Size

| Flat Bar (mm) | Round bar (mm) | |||

| Thickness | Width | Length | Diameter | Length |

| 12-280 | 2200 | 5800 | 16-450 | 3000-6000 |

5. Delivery state

A. Hot rolled or forged

B. Black surface

C. Q+T: hardness 28-34 HRC or Annealing:HBS<=235.

6. Delivery time

For abundant stock, 15-20 days.For customized products, 30-50 days.

We have full set of equipement (sawing machine/grinding/polishing

machine) to make customer's specification.

7. Our service

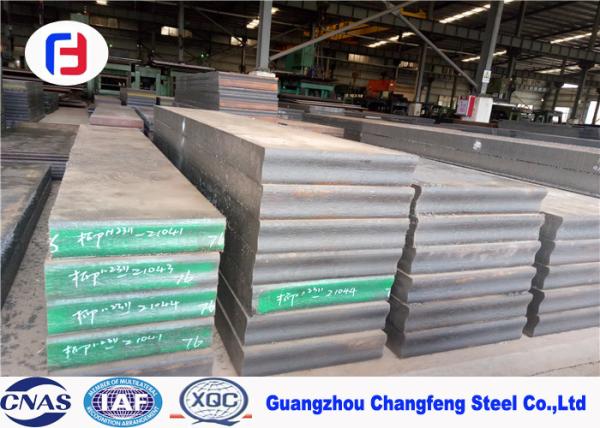

8. Product picture

Warehouse

Processing

Strict Quality Control

|