| Sign In | Join Free | My xpandrally.com |

|

| Sign In | Join Free | My xpandrally.com |

|

| Categories | Juice Filling Machine |

|---|---|

| Brand Name: | Aquatrin |

| Model Number: | RXGF |

| Certification: | ISO CE |

| Place of Origin: | China |

| MOQ: | 1unit |

| Price: | USD12000-50000 1Set |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10units per month |

| Delivery Time: | 45days |

| Packaging Details: | wooden package |

| Capacity:: | 2000-30000BPH |

| PLC&touch screen:: | Siemens |

| Driven Type:: | Electric |

| Product name:: | juice Filling Machine |

| Filling speed:: | 1000-6000 Bottles/h |

| Usage:: | Beverage Filling Packaging |

Containers and Specifications | ||||

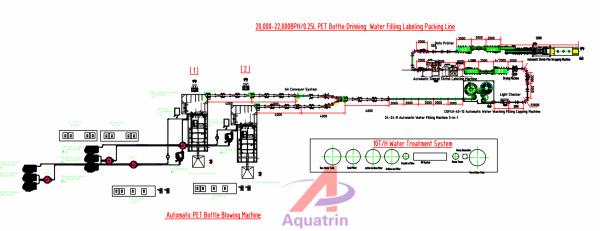

Project Name: Full Automatic Complete Juice(Fruit)Pulp

2000-20000bph Production Line | Hot Filling Fruit Juice | |||

Material | Shape | Filling volume | Filling level (mm) | Neck type |

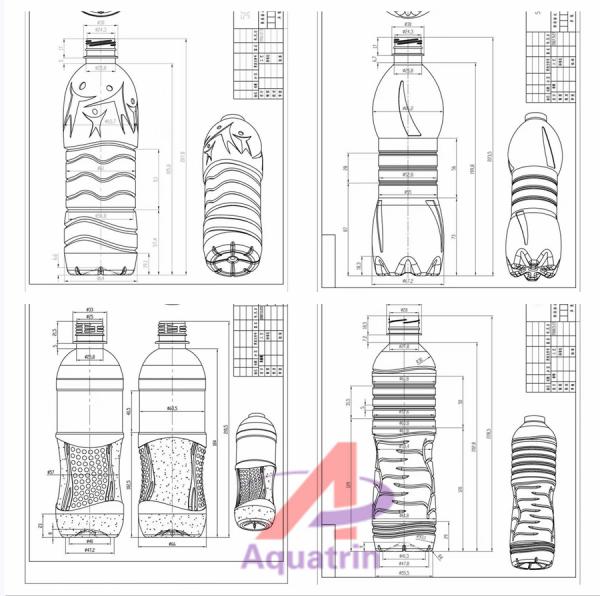

PET Bottle | Square or Round Bottle | 100-2000ml | Distance from bottle neck According request | As request |

Adjustable specifications of the bottle type | 【Middle Mould Base】Bottle diameter ≤105mm Bottle Height≤335mm | |||

Customers need to buy additional change-over parts for the

different bottles. If using square bottles, then bottle separating system will be added. | ||||

Juice Preparation | Fruit , Concentrate, Powder mixing, Pulp size≤15mm ..... | |||

Container Label & Control Mode | Packaging system | Palletizing system | ||

Hot Melt Roll-Fed PVC Shrink Label Full Label/ Half Label Manual / Automatic | Packing system | Min, Spec. | Manual Low position gantry palletizer Robot Palletizer High position gantry palletizer Single Arm Palletizer Manual Palletizer | |

Manual Film shrinker Wrap Around packe Robert Packing Machine | 1*2 2*3 3*4 4*6 3*5 | |||

User Ambient Conditions: | Temperature:10~40℃;Humidity:No dew | |||

User Electrical Supply Specification | Voltage:380V±5%, 3phase; Frequency:50HZ±1% | |||

Filling Part

Cap loading machine

We suplly Free Factory Layout design

We suplly Free Bottle Shape design

Water treatment system

Labeling Machine

Laser date printer

PE film wrapping package machine

Customer Photos

After Sales Service

1. Installation, debug

After equipment reached the workshop of customer, place the

equipment according to plane layout we offered. We will arrange

seasoned technician for equipment installation, debug and test

production at the same time make the equipment reach the rated

producing capacity of the line. The buyer need to supply the round

tickets and accommodation of our engineer, and the salary.

|